| Availability: | |

|---|---|

1. The 45 ° integrated bed body is made of high-quality cast iron material, with a high rigidity structural design. Adopting a right chip removal structure, it achieves a super large chip removal capacity, and can easily push out the water tank and chip removal machine for cleaning from the operating position without leaving space on the left, right, and rear ends of the machine. This makes the layout of the production workshop more flexible for users and facilitates the full utilization of factory space.

2. The guide rail adopts Taiwan's "Intime" high-quality widened line rail, greatly improving the rigidity and service life of the guide rail. Fast movement speed, good accuracy retention, simple maintenance, suitable for precision machining.

3. The spindle adopts a high-precision spindle, and the entire spindle assembly is subjected to high-precision dynamic balancing. The maximum spindle speed can reach 5000rpm.

4. The X/Z axis adopts Taiwan's "Intime" precision ball screw, which has fast movement speed, stability, and high accuracy.

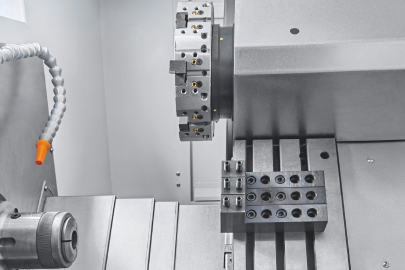

5.The standard configuration of the 5 machine tools is a tool arrangement structure, with an X-axis travel of 900mm Z-axis has a super large travel of 320 mm. It has the characteristics of fast tool changing, high reliability, and good rigidity; Optional servo power head and Y-axis side milling and drilling device can be equipped to achieve turning and milling composite function.

6.There are two lubrication methods for this machine: grease lubrication and oil lubrication. The screw bearing is lubricated with high-quality, high-speed, and long-lasting lubricating grease from Japan's NSK, which has a long service life and is maintenance free; The screw pair and guide rail pair adopt Taiwan Baoteng's thin oil automatic centralized lubrication system, which provides sufficient and reliable lubrication.

7. The standard configuration of the main motor adopts a 7.5 kW servo drive and a 5.5KW high-performance spindle servo motor. The spindle output torque is large, the speed is high, and the speed range is wide.

8. This machine tool can flexibly match various manual chucks, Taiwanese hydraulic power chucks, or spring chucks according to customer actual needs, and can also produce various special-shaped turning fixtures according to customer parts.

9. Using LED lighting: energy-saving, efficient, and long-lasting; Adopting a three color working status indicator light: real-time display of the working status of the machine tool, convenient for on-site visual management.

10. This machine tool has a compact structure, beautiful appearance, reliable semi enclosed protection performance, and smooth chip removal. High strength tempered safety glass windows, bright work lights, user-friendly operation height, and comfortable operation.

11. The hydraulic system is built-in and does not occupy additional space, making the equipment overall coordinated and aesthetically pleasing.

TECHINICAL PARAMETERS

Item | Unit | Model |

Max.rotating diameter on the bed | mm | 460 |

Max.imum turning diameter | mm | 300 |

Max.imum turning diameter of the drag plate | mm | φ100 |

Max.imumdiameter | mm | 45 |

Spindle end forms | A2-5 | |

Spindle hole diameter | mm | 56 |

Main shaft spped max | r/min | 5000 |

Number of spindle speed changes | cvt | |

power of the main motor | kW | 7.5KW |

Chuck model | inch | 6'' |

X-axis Travel | mm | 900 |

Z-axis Travel | mm | 330 |

X/Z setting the GO speed | m/min | 30 |

Knife holder form | Knife arrangement | |

Number of cutting tools | pcs | 8 |

Turning tool holder size | mm | 16×16 |

Boring bar diameter | mm | Φ20 |

Machine dimensions | mm | 2100×1500×1800 |

Weight of equipment | kg | 2650 |